Page 558 - Hydrover-hydraulic-integrated-circuits-catalogue

P. 558

Cetop 5 modular valves 59 SERIES

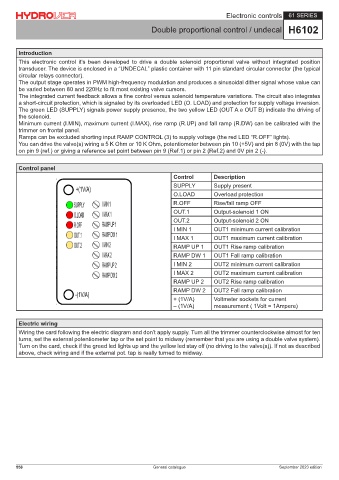

Cetop 5 modular poppet type solenoid operated directional valves H5911

between A1 and A / B1 and B

P

A B

70 T T

52 Dimensions in mm

79 90

3 3

1 2 180 2 1

305

4 5

T1 T1

A1 B1

P1

Technical data

Max. pressure Aluminium: 250 bar

Steel: 350 bar

Max. flow 130 lpm *

Weight Aluminium: 3,6 Kg

Steel: 7,7 Kg

Manifold material Aluminium or steel

N° Description Q.ty

1 Bosch Rexroth solenoid valve VEI-16-021-NC OD.15-X-21-Y-000000 * (normally closed) or 2

VEI-16-021-NA OD.15-X-21-Y-000000 * (normally open)

2 Bosch Rexroth coil D36 - CLASS H DIN 43650 ISO 4400 * 2

3 Connector DIN 43650 ISO 4400 2

4 Ø 6,5 through hole for mounting 4

5 OR 2050 i. Ø 12,42 cross section 1,78 5

* for complete technical information, click on the blue link or go to the components section at the end of the catalogue

558 General catalogue January 2025 edition